At Polgain, reverse engineering is a critical part of our work. Many of the engines we support are decades old, with no drawings or replacement parts available. By applying advanced metrology, CNC machining, and grinding expertise, we are able to recreate complex camshafts and camshaft sections with complete accuracy.

This post highlights the process we used on a recent project involving marine diesel camshaft sections.

Preparation and assessment

The process usually begins with customers providing photographs of their components for an initial budget quotation. If this is acceptable, physical samples are shipped to Polgain for full assessment.

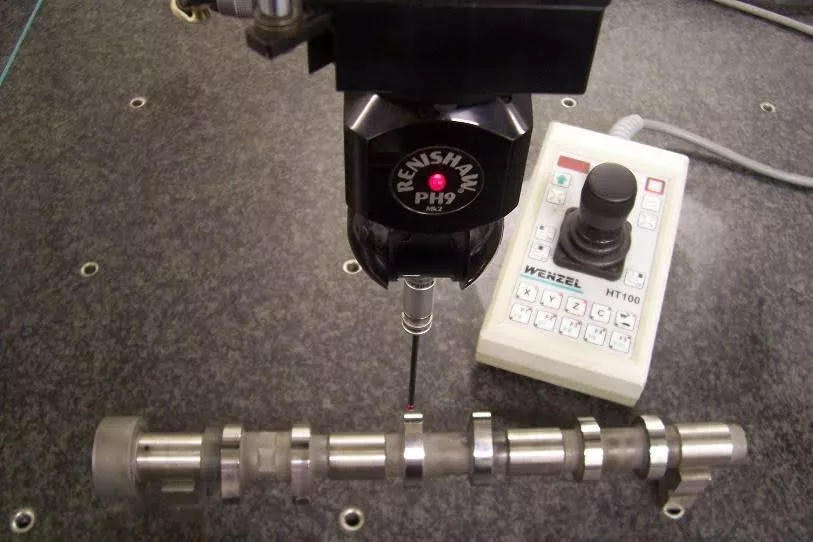

Once received, each component undergoes 100% measurement using our coordinate measuring machine (CMM) and one of our Adcole Cam Contour Measuring machines. Our engineers also assess evidence of heat treatment and make material grade assumptions to support the manufacturing process.

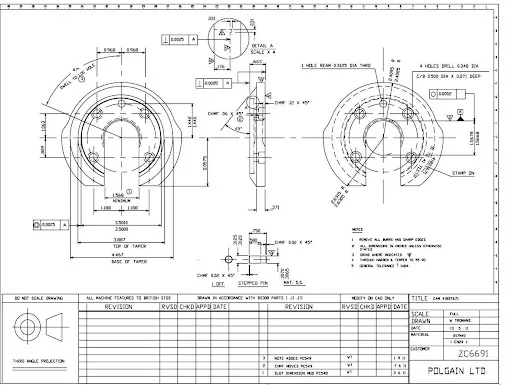

From this data, drawings and profile programs are generated for both cam cutting machinery and measurement equipment. Once approved, we procure material and begin production, a process that can take several weeks, depending on complexity.

Measuring and verification

Polgain operates two Adcole Cam Contour Measuring Machines, which are highly accurate instruments for recording cam profiles. They allow us to balance the cam profile, find the true peak (zero), and provide a digital output, particularly valuable for engine developers looking to refine or adapt existing designs.

During production, the Adcole machines are also used for quality control, producing deviation graphs and tolerance overlays. These, combined with CMM inspection reports, provide customers with detailed verification of their components.

Manufacturing before hardening

All materials are checked in under ISO9001:2015 procedures and allocated individual traceable numbers. Where required, for example, marine work, we accommodate Lloyd’s Register inspections during production. This typically involves one initial inspection upon arrival of the material and a final inspection upon completion of the work.

Initial machining is typically carried out on our Haas CNC lathes, though manual machines may also be used for one-offs requiring hands-on precision. Components that undergo large stock removal are stress relieved before machining continues.

Subsequent operations are carried out on our Haas VF6 machining centres, which deliver the tolerances and cutting times required for modern manufacturing. Datum holes are added for accurate positioning during profile generation and phasing. With all “soft” machining complete, components are then sent to our heat treaters for hardening.

CNC Capabilities

Our CNC department is equipped with a full range of Haas machines, including:

- SL30 high-torque lathe with live tooling and in-process steady for longer shafts.

- SL40 and ST40 turning centres.

- Three VF6 machining centres, one with a fourth axis for camshafts and others with extended fourth-axis capacity for plate and barrel cams. Along with many other batch production requirements such as holes, flats and shaped pockets.

This capability allows us to handle everything from single custom components to large-scale batch production.

Manufacturing after hardening

Once hardened, the parts are returned for final machining. They are registered in our system with full material and heat treatment certification for our customers’ reference.

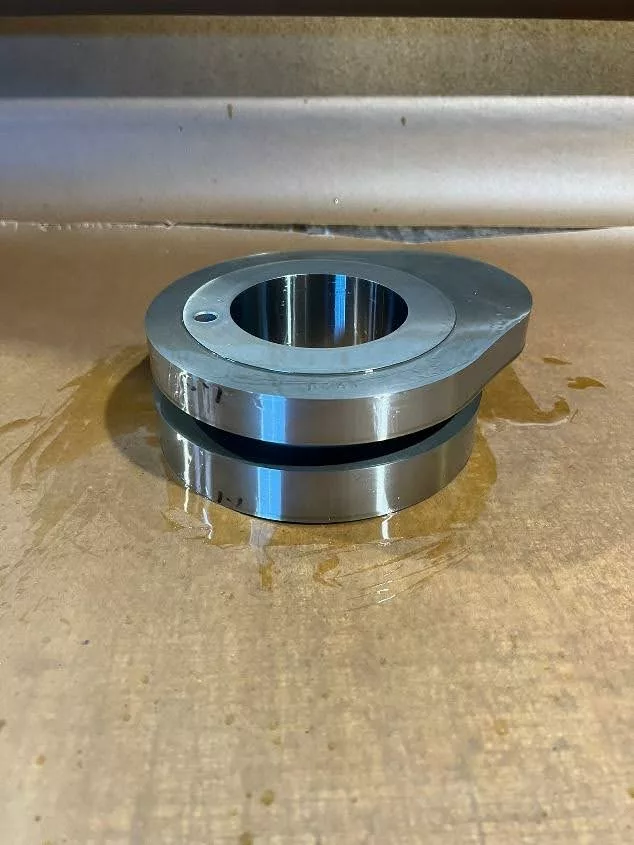

We begin by generating a stable location surface on our bore grinders using our Lumsden Plough grinder. Bore grinding follows, with operators carefully balancing tolerances against other critical dimensions on the part, for instance, cotter holes that may pass through the bore.

Final cam grinding is carried out on our Schiess Kopp CNC cam grinders, supported by a range of mechanical generation machines. This allows us to grind a wide variety of cams, including plate cams, barrel cams, swing arm cams, conjugate cams, globoidal cams and camshafts from small motorcycle types through to large marine versions.

All components are then inspected for size, profile and surface finish, with reports supplied where required for the customer.

Example: Rebuilding a 1929 Marine Engine

One customer approached Polgain while rebuilding a motor yacht originally built in 1929 by Krupp Germaniawerft. The vessel’s twin diesel engines are the oldest of their type still in service, and no drawings or parts were available.

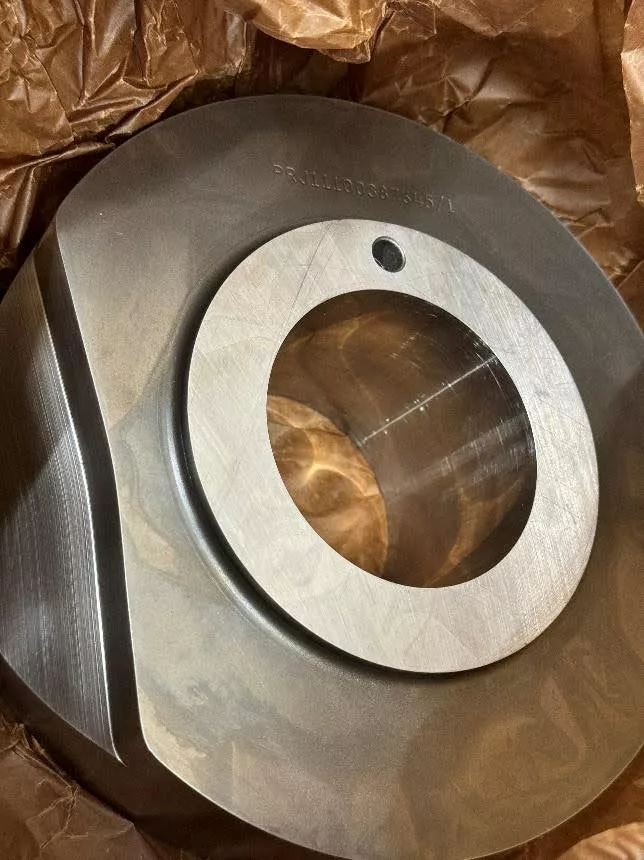

The project involved three cam types: inlet/exhaust, air start, and split fuel cams. Each required careful measurement and new drawings to be produced. Unique features included reversible operation, blended ramps, and radius-bottomed clamp holes for spill timing.

Working from supplied samples, Polgain manufactured new cam sets and coordinated international logistics to several locations around the world to support the staged rebuild.

Regrinding options

In many cases, cam regrinding offers a faster and more cost-effective alternative to full replacement. After assessing the component for depth of wear and hardness, we regrind back to maximum metal condition, checking hardness post-grind to ensure durability.

This approach can often deliver significant cost savings and reduced lead times.

Lead Times

Typical turnaround times at Polgain are:

- Regrind profiles (using existing data): 2 weeks

- Measure profiles and regrind: 3 weeks

- Manufacture cam (no treatment, from bar): 6 weeks

- Manufacture cam (heat treated, from bar): 8 weeks

- Manufacture cam (heat treated, from casting/forging): 12 weeks

- Add 2 weeks if measurement and drawings are required.

Through a combination of advanced measurement systems, CNC machining capability, and specialist grinding expertise, Polgain can reverse engineer even the most complex and obsolete camshafts. Whether regrinding worn components or manufacturing complete replacements, we provide solutions that extend the life of critical engines and reduce costs for our customers.