Maintenance, Overhaul, and Fluid Handling Systems

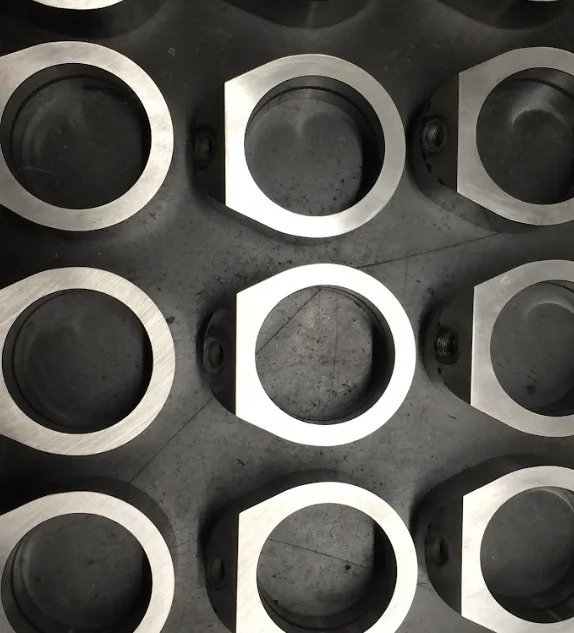

For planned maintenance or unexpected failures, fast-turnaround machining and regrinding services can help minimise downtime. Polgain works to assess worn components and determine whether regrinding, partial replacement, or full remanufacture is the most effective solution.

Bespoke components may also be applied to pumps, valves, and fluid handling systems where precision motion and reliability are critical. Accurate machining and careful material selection help support consistent performance across a range of operating conditions.

Control Machinery and Legacy Equipment Support

Custom-engineered parts can also be considered for control and processing machinery used within energy-related operations, including industrial processing, packaging, or refining equipment. Maintaining accurate motion and timing in these systems helps support consistent output and operational efficiency.

Polgain supports older or highly specialised machinery that is no longer supported by OEMs. Through detailed measurement and reverse engineering, we can manufacture replacement components that meet original specifications, helping extend the service life of legacy assets without compromising performance.