When a camshaft wears, performance suffers. Worn cam lobes, which control valve timing and movement, can lead to reduced efficiency, increased strain on surrounding parts, and even unexpected downtime.

Replacing a camshaft isn’t always the fastest or most cost-effective answer. Cam regrinding restores worn cam lobes to their original profile, extending service life at a fraction of the cost of a new component, and without the waste.

What is cam regrinding?

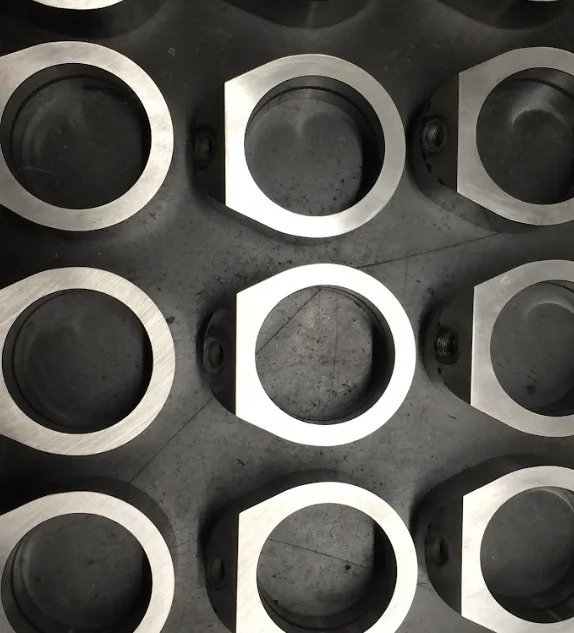

Cam regrinding reshapes worn or damaged lobes back to their original geometry and function. Using advanced machinery, such as Adcole Cam Contour Measuring Machines, we capture the exact cam profile and grind it back to precise tolerances. This ensures correct timing, lift, and duration for the specific application.

The financial benefits of cam regrinding

Cam regrinding is a straightforward way to give a worn camshaft a new lease of life. One of the most immediate advantages of cam regrinding is cost reduction. Manufacturing or sourcing a new camshaft, particularly for large engines or specialist equipment, can be expensive and time-consuming. Regrinding avoids these delays and costs while delivering performance equal to the original.

In one project, Polgain reprofiled four camshafts from a power generation engine by measuring unworn lobe areas, creating accurate profile data, and restoring each camshaft. This saved the customer the cost of four new units and reduced downtime significantly.

At Polgain we will regrind where possible, but if regrinding is not the right option we can manufacture a new camshaft to bespoke fit.

Protecting other parts

Incorrect cam lobe geometry can place extra stress on followers, bearings, and other valvetrain components, accelerating wear across the system. Regrinding restores the correct profile so all related parts operate as intended, reducing future maintenance needs.

Reducing waste and supporting sustainability

Beyond cost savings, cam regrinding aligns with environmental and sustainability goals. Such as avoiding the energy usage, raw materials, and emissions associated with producing a new camshaft.

By extending component life, you cut waste and support circular economy principles, without compromising reliability. This is especially important in industries such as pharmaceuticals, packaging, and power generation, where sustainability is under increasing focus.

The pros and cons of cam regrinding

Cam regrinding has many advantages, but like any process, it also has a few limitations. Understanding both will help you decide if it is the right approach.

The benefits of cam regrinding include:

- Extends the life of your existing camshaft without the cost of a full replacement

- Usually faster than sourcing or manufacturing a new camshaft

- Fits back into your system exactly as before, saving time on installation

- Reduces waste by making full use of the materials you already have

Points to keep in mind:

- The camshaft needs to be in good enough condition for the lobes to be restored

- In some cases, small adjustments may be needed to external components to achieve the correct valve clearances after refitting

- If the camshaft is badly damaged or excessively worn, manufacturing a new bespoke camshaft may be the better option

By understanding these points, you can make an informed decision about whether regrinding is the best route for your equipment.

When should you consider regrinding?

Cam regrinding is suitable when:

- Cam lobes show visible wear, pitting, or deformation

- Performance has declined due to timing irregularities

- The original cam profile is still available or can be replicated from unworn sections

At Polgain, we provide a full diagnostic, profile mapping, and precision grinding service to assess the viability of regrinding and deliver a long-lasting solution.

With decades of experience in camshaft manufacture, CNC machining, and precision grinding, Polgain delivers technically accurate, high-quality solutions for sectors from motorsport to power generation.

Please note: The camshaft you send us for regrinding must be in a condition that allows the lobes to be restored. If it is damaged or excessively worn, it may not be suitable for this process. In some cases, small adjustments may be needed to external components to bring valve clearances back into range once the camshaft is refitted. This can include using shims or, in rare cases, having cam carriers skimmed.

Want to get more life out of your camshafts?

If you would like to talk through regrinding or bespoke camshaft options, our engineering team is here to help. You can get in touch via our website or call us on 01502 532880 to discuss regrinding or bespoke manufacturing options.

FAQs

What is the turnaround time for cam regrinding?

Turnaround depends on the part’s condition and complexity, but it is often faster than sourcing a new camshaft.

Can you regrind any camshaft?

We handle a wide range, inspecting each one to confirm it’s suitable.

What if regrinding isn’t possible?

We can produce a new camshaft to your exact specifications.

Do I need to send the whole engine?

No. Only the camshaft is required.

Will a reground camshaft last?

Yes. When done correctly, a reground camshaft will deliver long-term performance equal to the original.