The Challenge

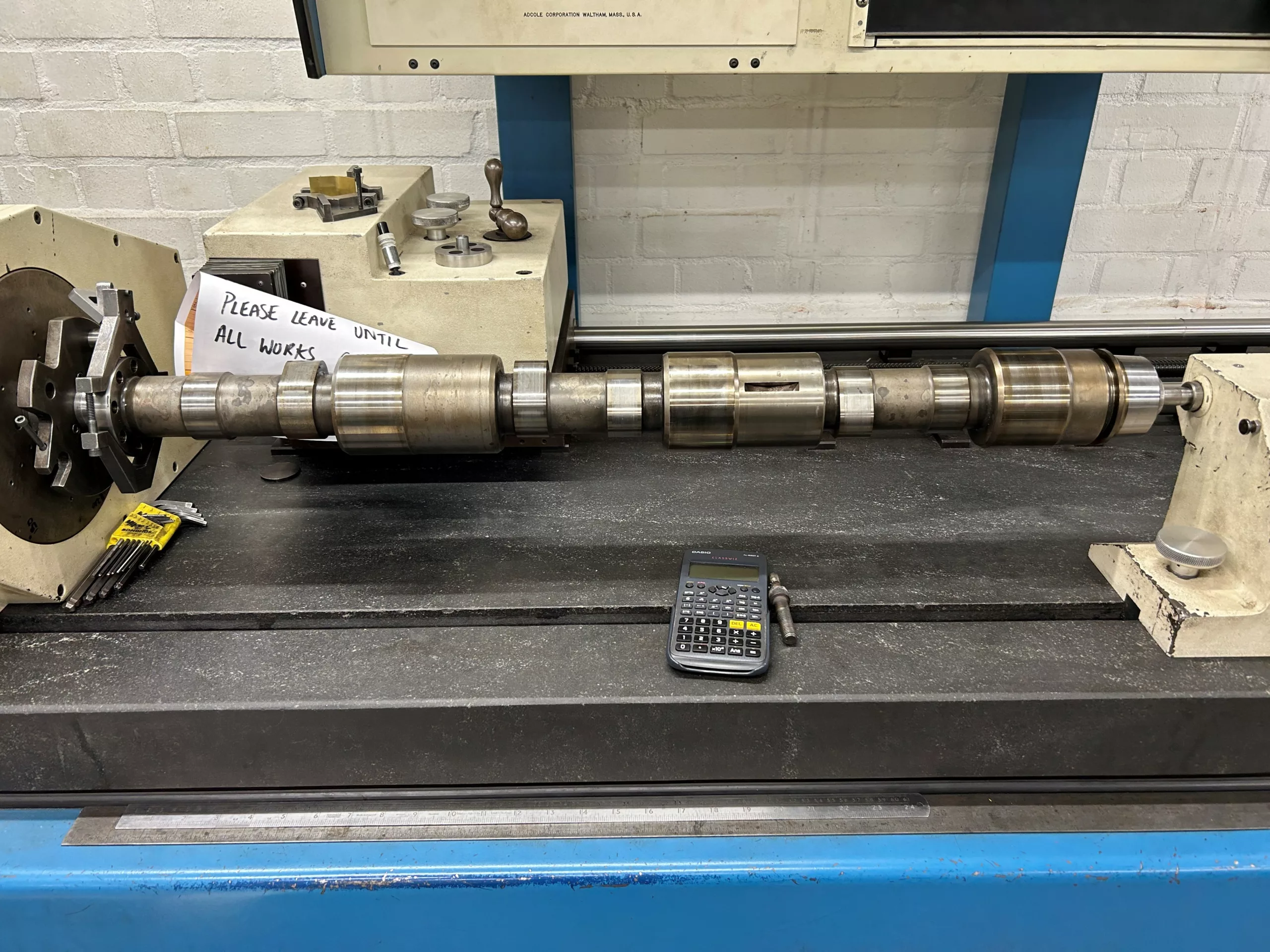

While carrying out routine maintenance on a large diesel engine used in power generation, a customer discovered significant wear and damage to the cam lobes on four camshafts. Replacing the camshafts with brand-new components would have been extremely costly and time-consuming, given the size and specialised nature of the parts.

The Solution

The four damaged camshafts were shipped to Polgain for inspection and assessment. Using one of our Adcole Cam Contour measuring machines, we accurately measured the unworn sections of the cam lobes to determine the original cam profiles. This data was then used to produce profile programs and engineering drawings, capturing the exact cam angles required for proper function.

Our team carried out a full regrind of all four camshafts, restoring the components to their original specifications and ensuring reliable performance without the need for total replacement.

The Outcome

By refurbishing the existing camshafts instead of sourcing new ones, the customer avoided the high cost and longer lead times associated with purchasing four bespoke components. The regrinding process not only extended the life of the original parts but also ensured the continued efficiency and reliability of the engine.

This project is a great example of how Polgain’s precision regrinding services can deliver cost-effective, time-saving solutions for critical industrial applications.