CNC machining capabilities

Our CNC machining services cover a wide range of requirements, from precision one-off components to full production batches. Capabilities include:

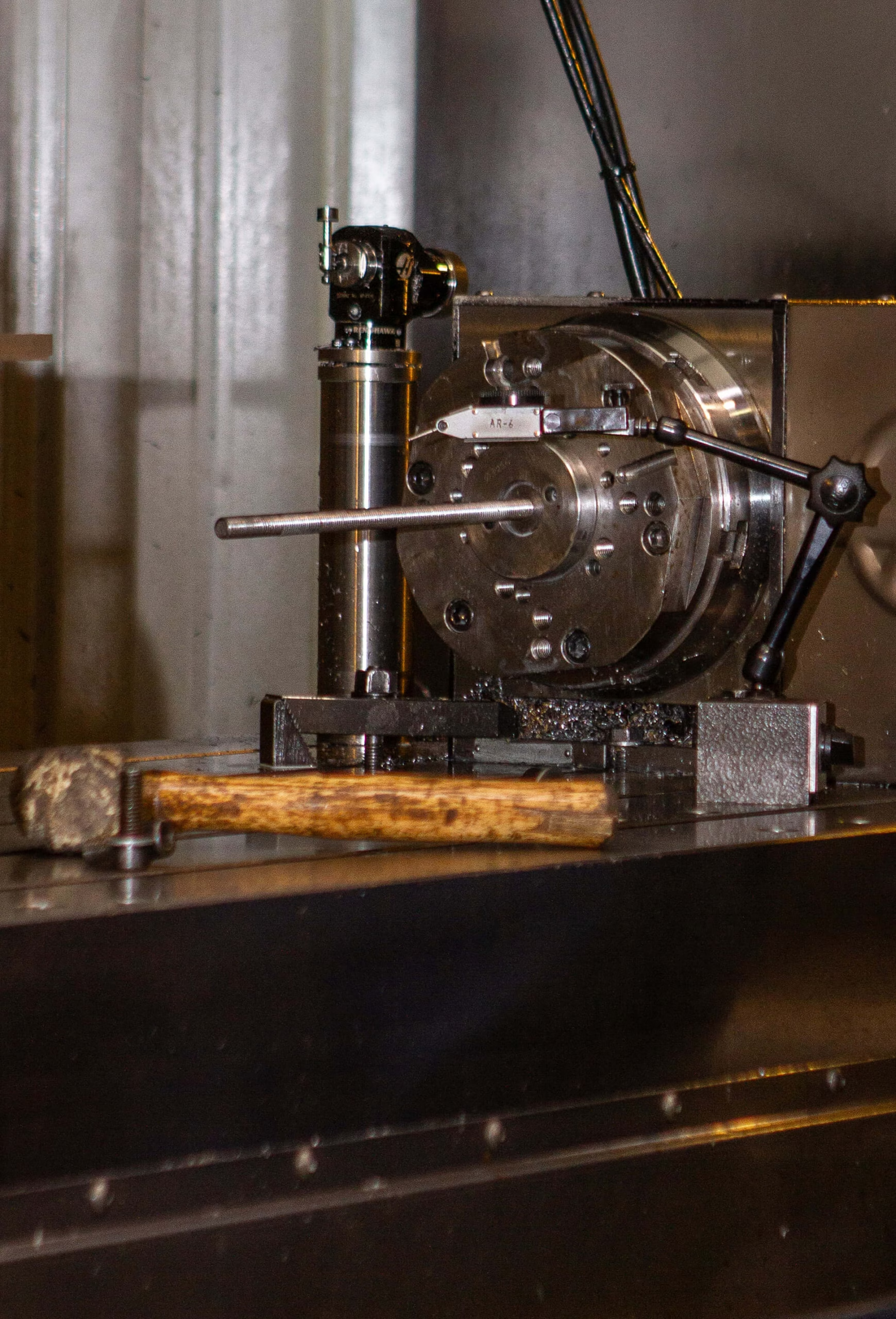

- CNC turning on Haas SL and ST series lathes, including live tooling and steady support for long shafts.

- CNC milling on VF6 machining centres, with 4th axis options for complex geometries and high repeatability.

- Prototype and small-batch machining for development projects.

- High-volume production runs with consistency and efficiency.

- Work with a variety of materials and grades to meet strength, durability, and heat-treatment requirements.

If you need hardened and ground cams, there is nowhere else that can do it in the UK.