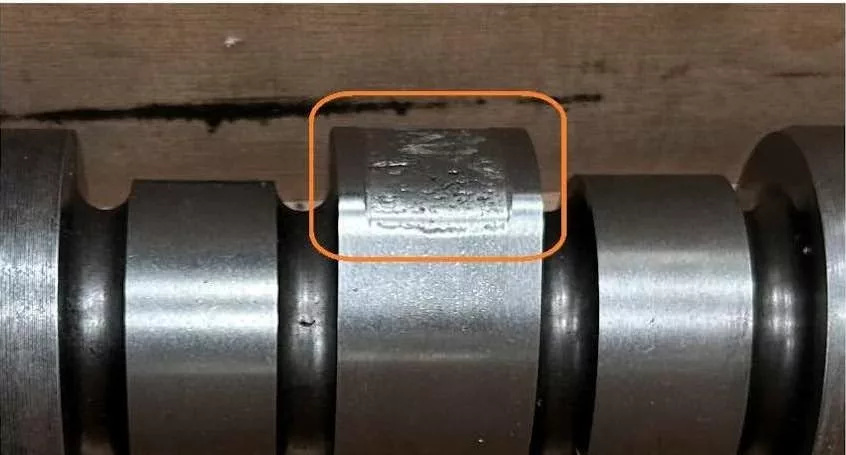

A new contact from the disaster recovery and generator sector came to us with two camshafts showing severe wear on several cam lobes.

In addition to the level of wear, the camshafts presented a significant practical challenge.

At 2.1 metres in length, they exceeded the capacity of our longest cam grinding machines, as well as most equivalent machines available in the UK.

Replacing the camshafts in full would have been costly and time-consuming, with extended lead times that risked prolonged downtime for critical standby power equipment.

The solution we put in place

Following detailed assessment and internal review, we proposed an alternative approach. The complete camshaft was fully measured and draughted, capturing all critical dimensions and cam profiles.

Rather than attempting to grind or replace the camshaft as a single component, we redesigned the camshaft as a split assembly, incorporating a precision-engineered mechanical joint at the midpoint. This design allowed:

- A new half camshaft to be manufactured

- Full heat treatment to restore durability and wear resistance

- Accurate integration with the existing serviceable half of the original camshaft

The Outcome

The redesigned, mechanically joined camshaft provided a reliable and proven solution.

Split camshafts are a recognised and established approach within the generator and heavy diesel sectors and offer greater reliability than welded and reground cam lobes, particularly for long camshaft assemblies.

By re-engineering rather than fully replacing the camshaft, we enabled the client to return their equipment to service with reduced cost, lead time, and confidence in long-term performance.

Why you can trust this approach

We have designed and manufactured cams and camshafts since 2002, working with customers who rely on heavy-duty machinery every day. Our team specialises in large and complex camshaft assemblies, including one-off repairs and reverse-engineered parts where full replacement is not practical.

As the only independent cam manufacturer in the UK, we support sectors such as power generation, marine, packaging, and heavy industry. Many of the components we work on are critical to keeping equipment running safely.

Our engineers work to ISO 9001 standards. Every project starts with careful measurement, clear drawings, and open discussion about what will work in service. This experience allows us to offer practical options like split camshaft designs when standard repair routes are not suitable.

How we can help you

If you are dealing with worn camshafts, long lead times, or parts that do not fit standard machines, there may be more options than full replacement.

Call us on 01502 532880 or email sales@polgain.com, and one of our engineers can review your situation and advise on the most suitable next step.